After I finished the engine shed, it is now time to finish off the rest of the service area scene at Elizabeth Oaks.

With a tweak in the general track arrangement I was able to have one dedicated track for fuel/sand loads and for caboose storage behind the two main engine tracks. Now I had to find the perfect place for the sanding tower to serve both engine tracks

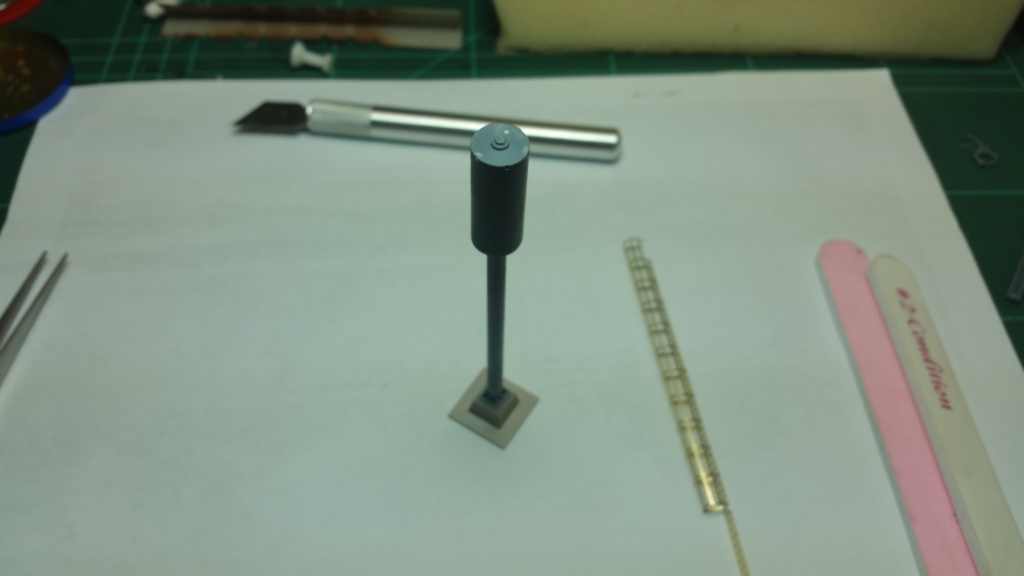

The photo below shows the overall scene with a raw assembled Walthers kit.

As the overall look of the tower dimensions seem to be correct, I found that the included ladders and safety railings are out of scale. I decided to add some etched brass ladders to the tower and replace the plastic railings and pipes with some scratch built ones.

After I assembled the tower structure, I removed the molded eyes for the railings and all other braces and filled the gaps and holes with putty.

The safety ladders were easy to set up, I cut out the ladder from the sprue and gently wrap the cage around a stick to get the round shape. With this done I soldered the cage to the ladder leaving the cage one section longer than the ladder top.

I added bracings made of brass wire to the ladder, drilled holes into the tower head to plug in the bracings. The safety railing are made out of brass wire and soldered together using a drawn template.

Also the sand pipes are soldered after a drawn template, I adapted the height and length to match my given situation.

The photos below show a final test fit to ensure the overall appearance is pleasing. The container incorporates the sand dryer and compressor. Sand hoses are made from black single stranded wire.